Pavithra KV

Bandhan

The Zen path of Wood and Clay

Individual Project

- Project Duration : 16 weeks

Crafted from wood and terracotta, this versatile furniture piece is designed for public parks. It seamlessly adapts to diverse weather conditions and enhances group activities. Moreover, it evokes nostalgic memories, adding an extra touch of sentimentality.

Design

About

This product endeavors to explore the distinctive attributes of wood and clay and how they complement each other in the creation of furniture inspired by Zen philosophy.

The objective is to cultivate a unique artistic expression utilizing these materials and examine their potential for application in park furniture.

Additionally, the project seeks to investigate the capacity of wood and clay to retain warmth during winter and maintain a cool temperature in summer. The resultant park furniture will seamlessly integrate with its surroundings and will be thoughtfully designed to evoke nostalgic sentiments while advocating for the enduring and sustainable utilization of materials.

By challenging prevailing approaches to public furniture design, this project aims to offer a fresh perspective on the utilization of natural materials in urban environments.

Prototype in Use

Usually most public furniture around us is made of Iron, Concrete or stone. These materials tend to get extremely hot during summers and cold during winters making is uncomfortable to use.

By utilising and exploring the properties of Terracotta and Wood a public furniture has been designed that addresses the need.

Research paper link

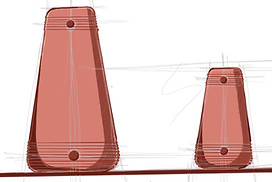

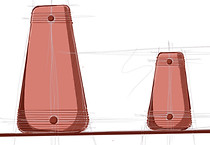

Form

Based on form study achieved from terracotta

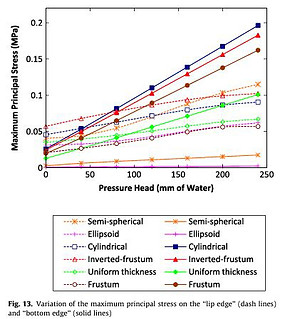

a) The lower stress concentration observed in

terracotta can be attributed to the rounded

shape of their bottom edges.

b) In terms of stiffness, a frustum-shaped

module with uniform thickness demonstrates

greater rigidity.

c) On the other hand, an inverted frustum

exhibits the lowest level of stiffness.

Frustum of uniform thickness of 15mm with circular base. This form also helps in distributing the load uniformly over a larger area.

What makes this form effective

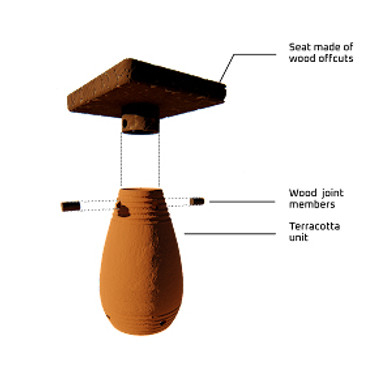

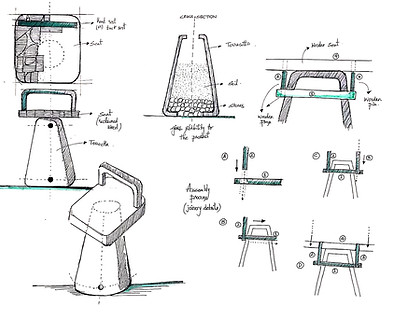

Combinations of use of the terracotta unit

Possible arrangements of the furniture

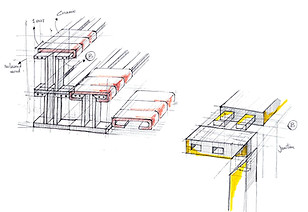

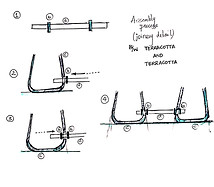

Joinery detail of backrest to seat

Types of wood used

Keekar

Bakan

Pepal

Poplar

Neem

Eucaluptus

Joinery detail of seat to terracotta unit

Research and Exploration

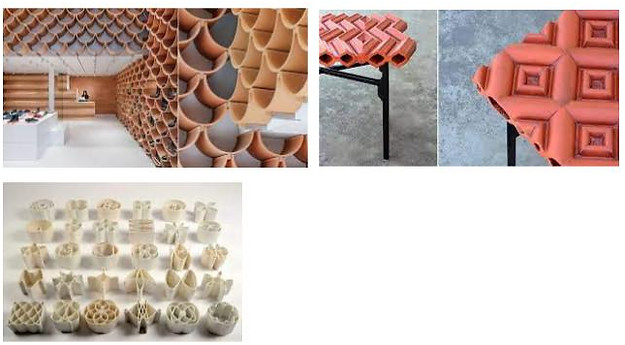

The philosophy of Zen emphasizes the importance of simplicity. It involves expressing ideas and functions without being excessive or showy. Zen encourages the seamless integration of objects into their environment, allowing them to blend in and highlight the natural essence of the product.

In my designs, I strive to understand the inherent properties and visual appearances of wood and clay. By staying true to the materials, I worked on simple forms that showcase their natural beauty. I believe that through this approach, the materials are able to express themselves and reveal their true nature.

Study of various material explorations

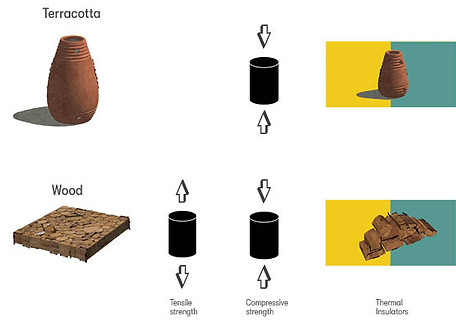

Wood

Wood is a versatile and natural material known for its strength, durability, thermal insulation, acoustic properties, and aesthetic appeal.

-

It is a naturally strong material, good in both compression and tension.

-

It’s excellent reaction to different weather conditions.

-

Wood offers a wide range of grain patterns, colors, and textures, making it visually appealing.

-

Wood is relatively easy to work with using common tools. It can be cut, shaped, carved, and joined

Clay

Rocks erode into clay over time, with the mineral composition determined by the region and type of rock.

-

Plasticity when wet and hard when dried or fired.

-

It’s excellent reaction to different weather conditions.

-

Clay containing iron-oxide are called either Terracotta or Ceramic and the one without iron-oxide content is Porcelain.

-

Grog is an additive to clay, more the content less the shrinkage and vise versa.

-

Grog is usually sand or finely powdered fired clay.

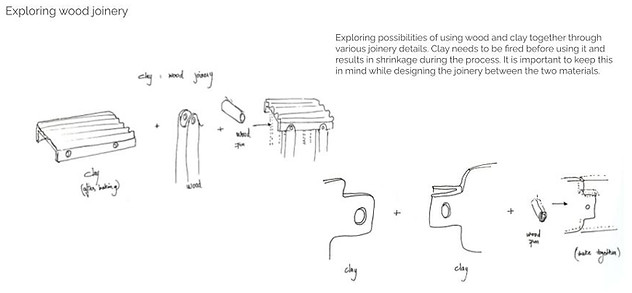

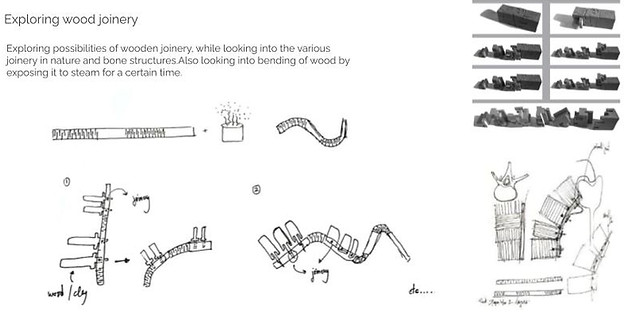

Different explorations were undertaken to examine the potential combinations and applications of these two materials. Alternative treatments and approaches were tested to discover new possibilities. Here are a few examples of the explorations conducted.

Self-explorations of wood and terracotta

Research paper link

Understanding terracotta forms, their stability and strength

Form of Terracotta unit

In terms of stress on the bottom edge, the

order of effectiveness (from best to worst) is as follows:

Ellipsoidal model, semi-spherical model, uniform thickness frustum-shaped model, frustum-shaped model, inverted frustum model, and cylindrical model.

The lower stress concentration in ellipsoidal and semi-spherical is attributed to the rounded shape of their bottom edges.

Compared to the frustum, the uniform thickness frustum has a thicker wall and therefore exhibits greater stiffness. On the other hand, the cylindrical form appears to be the least effective due to the impact of bending moments.

When considering stresses on the lip edge, the order of effectiveness (from best to worst) is as follows:

Frustum-shaped model, ellipsoidal model, uniform thickness frustum-shaped model, cylindrical model, and inverted frustum model.

Development

Area of Interventions

Stoneware : Non-flammable

Heat-resistant

Resistant to liquids

Keeps the contents inside cool

Wood : Poor conductor of heat

Light in weight

a) Fire-resistant electrical appliance for maximum safety and reliability.

b) Temperature-resistant products using stoneware and wood to protect users from harm and withstand temperature variations.

c) Explore wood and clay as eco-friendly alternatives to replace plastic products, reducing plastic pollution and its environmental impact.

Area of Development

Through the utilization of the thermal properties and strength inherent in wood and clay, the aim is to design park furniture that is not only sustainable but also environmentally friendly.

Concept development

Final concept development

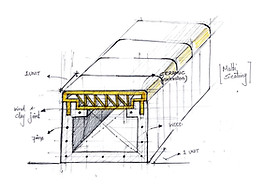

Construction

Prototyping

The transition from design to prototype was an immersive and practical learning experience that provided valuable hands-on knowledge. It enabled me to grasp the intricacies of material manipulation, production methods, and advancements in design, all while actively participating in the construction phase.

Throughout this journey, I embarked on various stages, which included engaging in insightful discussions with seasoned potters to ascertain the exact specifications of the terracotta units. Factors such as thickness, strength, and desired dimensions were carefully considered during these conversations. Furthermore, I actively sought out remnants of wood from sawmills, meticulously selecting the most suitable type with optimal grain density and texture.

Making process

Construction drawing